Decarbonising And Grinding In Of Valves

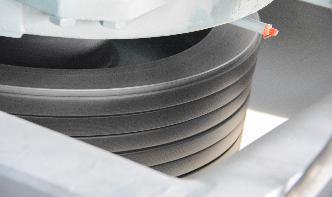

Polish the valve heads and the radii under the heads, but be most careful not to remove any metal from the valve stems. Deal with the valves one at a time and coat each seating lightly with valve grinding paste. The fine grade is usually best. Push the valve into place and grind it in by holding the stem in a collet or valve grinding tool.